Metal Stitching- RA Power Solutions

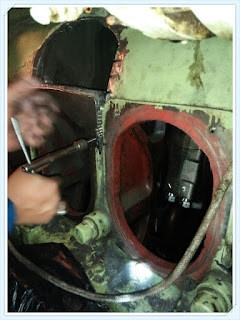

RA Power Solutions with experience of more than four decades. We have experienced technicians who have undertaken most complex crack repair jobs by metal stitching and metal lock process. The technicians carry pneumatic portable tools and consumables to the site. We have executed thousands of repairs of cracked components, broad description of which is as following: I) Repair of heavy earthmoving and mining machinery. II) Repair of high capacity turbines, alternators, turbocharger casings and parts. III) Cracked engine blocks , cylinder heads, pistons, cylinder liners. IV) Heavy duty industrial machine. Visit Us: http://www.marineengine.in/blog/2019/10/08/repair-of-crack-cast-metal-by-metal-stitching-metal-stitching-services-ra-power- solutions/ #MetalStitching # engineblockrepair # metalsurgery